RESTAURANTS, HOTELS, PUBS, NURSING HOMES, DELICATESSENS, TAKEAWAYS,HOSPITALS, BAKERIES AND FRANCHISES.

RESTAURANTS, HOTELS, PUBS, DELIS, .

ABOUT THE FATSTRIPPA G.R.U

HOW THE FATSTRIPPA WORKS

ADVANTAGES

- Removes FOGs to less than 35 million parts per million.

- Eliminates the need for treatment with chemicals or emzynes

- Easy to maintain.

- Recovered F.O.G.s have less that 3% Water content

RELIABILITY

- No moving parts or circuit boards.

- No electrical breakdown.

- easily retro-fitted into existing kitchens

- range. of sizes to suit all kitchen needs from 0.5 to 6.5 litres per second.

DESIGN

- Constructed of high quality 3mm 316 grade stainless steel.

- High quality neoprene seals.

- Designed for easy cleaning and maintenance.

- 10 year construction warranty.

COMPLIANCE

- Approved by Irish Water under the F.O.G program.

- Meets the PDI-G-101 standard to which all automatic grease trap must comply.

THE RANGE OF FATSTRIPPA UNITS

THE RANGE OF FATSTRIPPA UNITS

FATSTRIPPA F/S 50 (SMALL BISTRO)

FATSTRIPPA F/S 70 (SMALL BISTRO,CAFE 1-2 SINKS)

FATSTRIPPA F/S 100 (1-2 COMMERCIAL SINKS)

FATSTRIPPA F/S 115 (1-2 COMMERCIAL SINKS )

FATSTRIPPA F/S 150 (2 SINKS+ COMBI OVEN )

FATSTRIPPA F/S 220 (3 SINKS+ COMBI OVEN )

FATSTRIPPA F/S 360 (MULTIPLE KITCHENS )

FATSTRIPPA F/S 650 (FOOD PROCESSING PLANTS )

HOW THE FATSTRIPPA WORKS

Fatstrippa revolutionised the grease management industry when it was introduced 22 years ago.

THE CONCEPT

WHAT IS FATSTRIPPA ?

- The Fatstrippa is an immiscible liquid separator, which operates utilising hydrostatic pressure and does not require any moving parts.

- It simply utilises the difference in specific gravity between oils and water to operate a one way valve that ONLY allows oil to be discharged.

HOW EFFECTIVE IS THE FATSTRIPPA ?

- The Fatstrippa will remove Fats, oils and greases from wastewater to below 35 parts per million.

- This is much lower that the required threshold set out by councils under the fog program.

THE OPERATION

WHAT HAPPENS TO THE RECOVERED OIL ?

- The recovered oil has a water content of less than 3%

- Because the fatstrippa is so effective in separating Fats , oils and greases from water , the recovered oil can be processed without any de-watering to biodiesel.

- Simply empty the recovered oil into your oil collector for return to your oil supplier

WHAT ABOUT SOLIDS BEING FLUSHED INTO THE UNIT ?

- The waste water is strained through a 3 mm mesh basket upon entering the unit thereby removing solids.

- The incoming effluent enters the Fatstrippa unit whereupon all large food solids are removed by the strainer basket.The effluent then passes under the first weir and into the main separation chamber

HOW DOES THE SEPARATOR WORK ?

THE SEPARATION PROCESS

The main separation chamber is contained under the horizontal plate,which is shaped in such a manner as to concentrate the serparated Fats Oils and Greases in one area underneath the oil outlet valve whilst minimising dead space in which fats could congeal.

HOW DOES THE BALL VALVE WORK ?

FLOATING BALL VALVE

The oil outlet valve consists of a bossed gutter and ball made of a material with an extremely accurate and stable specific Gravity, which allows the ball to float on the interface between the de oiled effluent and the F.O.G’s

MAINTENANCE

THE DESIGN PRINCIPLES.

FATSTRIPPA IS DESIGNED TO LAST AND MINIMISE MAINTENANCE

The Fatstrippa was designed around the principles that it should be robust,minimise environmental impact, easy to clean, eliminate chemical and f.o.g contamination of the waterways and oceans.

WHAT MAINTENANCE IS REQUIRED ?

The Fatstrippa is simple to maintain on a daily basis.

- EMPTY STRAINER BASKET.

- EMPTY OIL CONTAINER BASKET.

- CLEAN BALL VALVE WITH TUBE BRUSH SUPPLIED.

- OPEN SILT VALVE FOR 10 SECONDS TO FLUSH SETTLED PARTICLES FROM THE BASE OF THE UNIT.

- WIPE DOWN EXTERNAL SURFACES OF THE UNIT.

WHICH FATSTRIPPA DO I NEED?

Fatstrippa comes in a range of sizes and optional variations to ensure you have the right unit for your kitchen

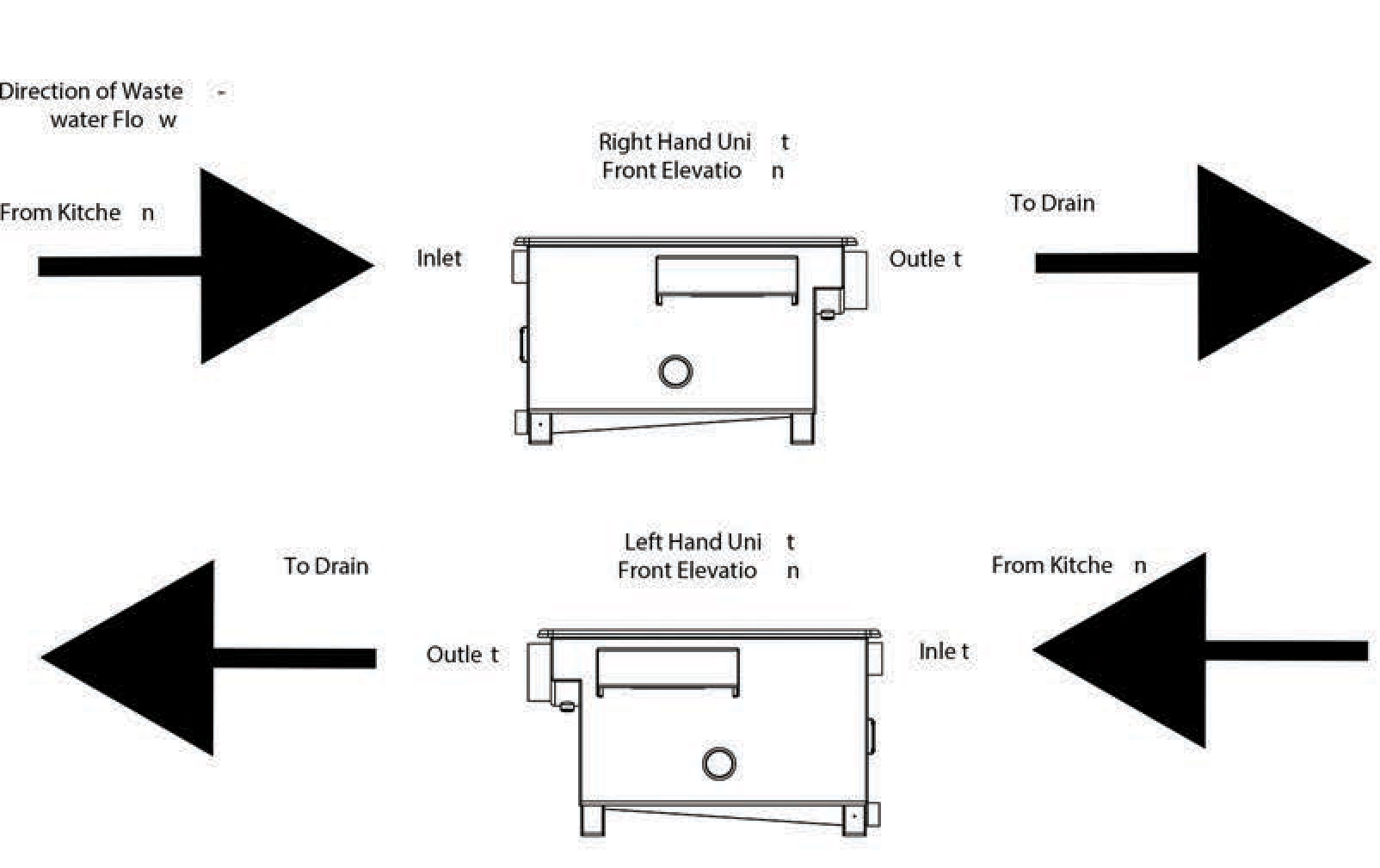

LEFT HAND OR RIGHT HAND MODEL

Fatstrippa comes in left or right hand variations.

The reason for this is to minimise the dead spacewithin the unit, and to maximise the pumping action the design of the unit facilitates.This minimisation of dead space increases the time required between maintenance, eliminates F.O.G Stasis in the units and most importantly maximises the F.O.G recovery.

The choice of left or right hand unit will normally be left to the technician fitting the unit.

REAR INLET MODEL

At Fatstrippa, we understand the space constraints within your kitchen , so to aid with ease of fitting we have developed a rear inlet model which can reduce pipe runs and add flexibility to the location of the unit.

RAISED OR FLOOR MOUNTED ?

It is generally a personal preference as to whether you have a floor mounted or raised unit installed.There are a number of sizes of extension legs available to raise the height of the Fatstrippa further

THERMOSTAT OR INTEGRATED TIMER/THERMOSTAT HEATER.

The Fatstrippa heater element only operates when the temperature of the unit drops below 30 deg Centrigrade.As most water entering the unit is significantly above that temterature the Heater Element operates only intermittently during the hours of operation.A timer controlled element is available to ensure the element only operates during hours of kitchen operation.

STANDARD OR EXTENDED BASKET

For kitchens that discharge large amounts of solid waste in their waste water, the extended basket can be a useful option.It has approximately double the capacity of a standard basket and adds approximately 200 mm to the length of the unit

FLOUR SPECIFIC STRAINER BASKET

Flour and other starches combine easily with F.O.Gs to form a solid crud that impacts the operation of the all grease traps and removal units.At Fatstrippa we haver developed a basket that maximises the recovery of the flour and starches prior to it entering the init.